Pneumatic slurry pump

FY-0.8T Pneumatic Slurry Pump

1、Product Overview

Zhilong's newly launched Type 3A sanitary quick-release pneumatic slurry pump finds extensive application across industries including artificial leather, transfer film leather,

calendered leather, colour-coated steel sheets, printing and dyeing, pharmaceuticals, coatings, chemicals, textiles, spray painting, spraying, aluminium-coated film, and colour

steel roofing tiles. Suitable for conveying high-viscosity chemical slurries (VIS ≤ 120,000 cP at 25°C), it features explosion-proof, corrosion-resistant, anti-sedimentation properties

alongside low noise and energy-saving capabilities. This versatile mobile conveying equipment offers exceptional adaptability.

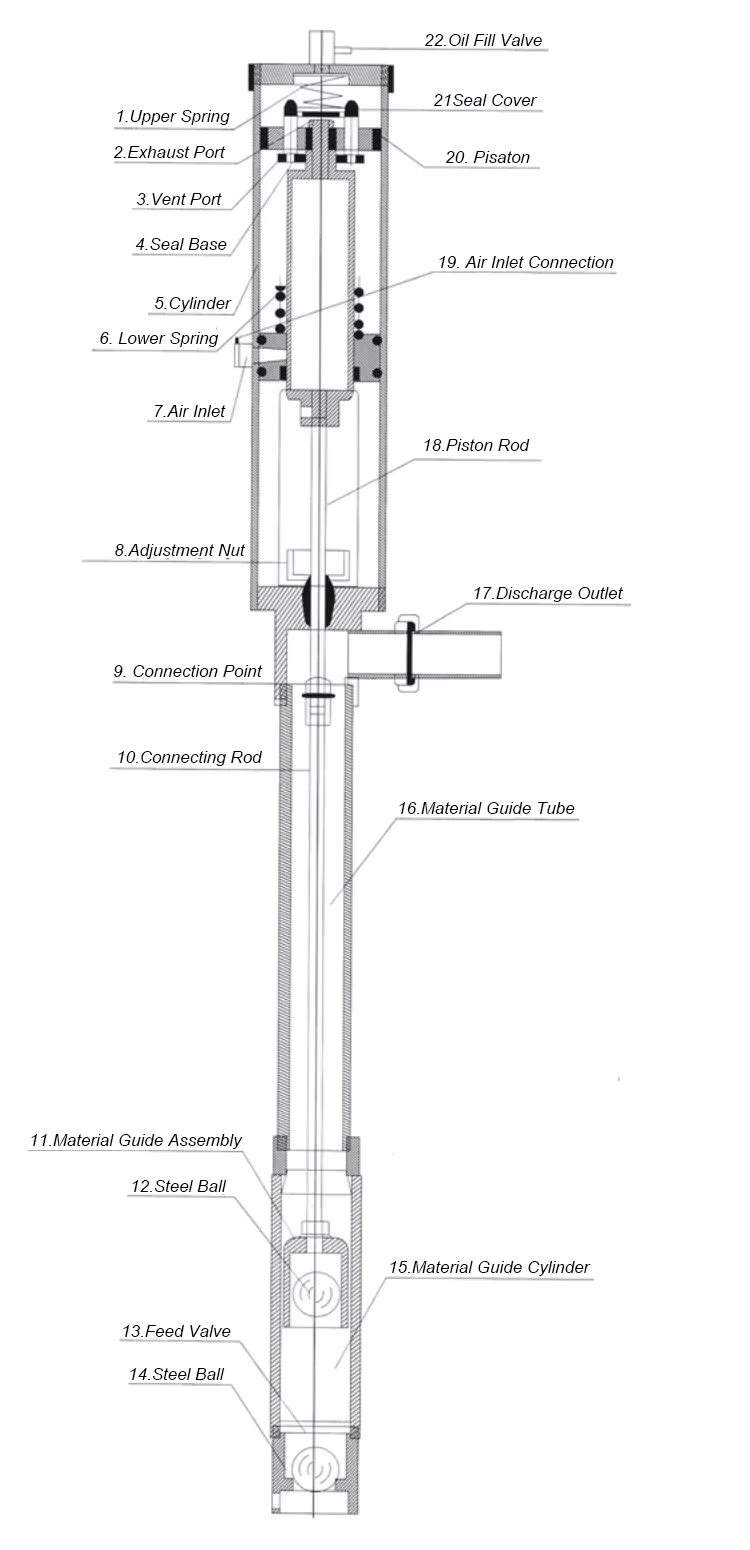

2. Structure and Principle

The pneumatic slurry pump comprises two cylinders, each fitted with an inlet valve, suction valve, and discharge valve. Compressed air sequentially passes through the pneumatic

plunger-type cylinder assembly, utilising the pressure differential between compressed air and exhaust gas to drive reciprocating motion. This action engages the pneumatic

plunger pump – the upper piston of the slurry pump – via connecting rods, thereby facilitating the suction and discharge of slurry. This constitutes a pneumatic pump with

explosion-proof characteristics.

The FY series utilises air pressure differential to drive the piston's vertical motion, thereby actuating the feed piston's opening and closing to achieve material lifting. Specific

configuration as per diagram.

3、Operating Instructions

(1) First insert the entire pump hose into the barrel to be transported, maintaining as vertical an orientation as possible.

(2) Secure the pump hose, tighten the corrosion-resistant hose at the pump inlet and outlet, and ensure the outlet is connected to the designated safe feed position.

(3) Close the air inlet valve, then connect the air supply hose to the inlet fitting. Open the air inlet valve to the required slurry flow rate to regulate the pneumatic pump's operating frequency, and commence operation.

4、Maintenance and Servicing

(1) During operation of the pneumatic slurry pump, prevent impact deformation of cylinder components, which may cause piston seizure and result in scrapping.

(2) After one million piston strokes, clean the cylinder based on moisture accumulation during air compressor operation and apply No. 30 lubricating oil.

(3) Depending on air source quality, it is advisable to install a pneumatic three-way valve with automatic oil injection before the inlet.

(4) For prolonged storage, flush with solvent under operating conditions to prevent slurry freezing and conduit blockage.

5、Precautions

(1) Should the cylinder body become hot during operation, immediately add or replace with 30# lubricating oil.

(2) Should leakage occur after adjusting worn seals during use, promptly adjust the regulating nut or replace the PTFE regulating shim.

6、Advantages

(1) Constructed from 304 stainless steel, suitable for media including vegetable oils, chemical liquids, diesel fuel, and edible oils.

(2) Pump body exhibits corrosion-resistant properties.

(3) Features fluororubber seals resistant to chemical corrosion.

(4) Fitted with a 220V, 550W standard motor; not suitable for petrol.